Best quality China Customized Hot Forging Excavator Spare Parts Applied in Construction Machinery Field

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for Best quality China Customized Hot Forging Excavator Spare Parts Applied in Construction Machinery Field, We have now confident that we can easily offer the premium quality products and solutions at resonable price, good after-sales services into the buyers. And we’re going to produce a dazzling future.

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for China Forged Excavator Parts, Rubber Track Pad, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

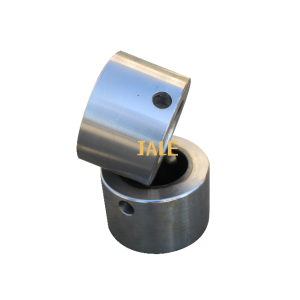

Product Details

|

Bucket Pin |

|||

|

Material |

45# |

Part No. |

PC300; EX100;CAT215;CAT225;JS200;D60… |

|

Color |

Bule or Customer Required |

Logo |

JALE or Customer Required |

|

MOQ |

10pc |

Packing |

Plywood Pallet or Customer Required |

|

Delivery time |

15-20days(one container) |

Suitable machine |

All Brands |

|

Warranty |

36 months |

Loading port |

Qingdao; Lianyungang; Rizhao… |

|

Certificates |

ISO9001,SGS |

Payment |

T/T;L/C; Ail Trade Assurance; Western Union… |

Appearance and process: Adopting medium frequency heating, hot forging process, or cold forging process of multi- location molding machine, then net belt heat.

Surface treatment available: Zn- Plated, Ni- plated, Passivated, Tin- plated, Sandblast, Polish, Electro Painting, Chrome plating; Hot Deep Galvanizing(H. D. G. ) etc.

Heat Treatment: Tempering, Hardening, Stress Relieving.

Details Display

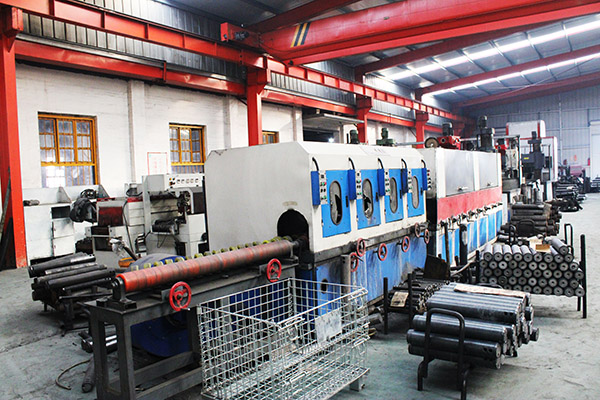

Production Process

Features

Crack Resistance and Abrasion Resistance

After quenching and tempering, the pin undergoes mid frequency induction hardening, which ensures sufficient core strength and wear resistance of the external surface.

After carburization, the pin bush undergoes internal and external mid frequency induction hardening, which ensures reasonable core hardness and wear resistance of internal and external surfaces.

Excellent lubrication performance

The most practical 8-shaped oil groove is adopted to ensure that the bushing has the best lubrication effect and prolong the service life of the bushing.

Longer Antirust

The original bucket bushing has been wiped with the good antirust oil and well packed, the black one has been finished with electrophoresis treatment, which ensures our bushing can be kept for a long time

Packaging

Parameters

|

Bucket Pin |

|||

|

Diameter |

Length Range |

Diameter |

Length Range |

|

13 |

45-160 |

70 |

113-650 |

|

15 |

45-158 |

76 |

146-463 |

|

20 |

48-165 |

80 |

210-740 |

|

25 |

71-173 |

85 |

210-1050 |

|

28 |

45-125 |

88 |

140-710 |

|

30 |

75-193 |

90 |

133-800 |

|

32 |

88-241 |

95 |

210-990 |

|

35 |

103-260 |

100 |

120-960 |

|

38 |

123-227 |

105 |

315-1001 |

|

40 |

150-285 |

110 |

260-1040 |

|

45 |

185-298 |

115 |

290-1040 |

|

50 |

79-371 |

120 |

282-870 |

|

52 |

115-805 |

126 |

300-925 |

|

55 |

105-900 |

130 |

256-980 |

|

57 |

122-1020 |

134 |

278-980 |

|

60 |

170-1020 |

145 |

295-1080 |

|

65 |

119-699 |

150 |

338-1290 |

|

Be customized according to customer requirements |

|||

Structures

Why Choose JALE Bucket Pins?

Choosing a good bucket pins manufacturer mainly depends on two points: one is that the quality of the product must pass, because the quality of the product directly affects the use of customers, the bucket pin is a vulnerable product, so the wear life directly affects customer satisfaction Spend!

The second is the price. In terms of price, JALE bucket pin axle maintains an absolute advantage in the market, especially for dealers. Under the environment of the new normal of the market economy, demand is declining, and only a more advantageous manufacturer can hold profits. To survive, we use automated mechanized production to effectively control the process to improve production efficiency, thereby reducing production costs, so we now have an absolute price advantage compared with other products!With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for Best quality China Customized Hot Forging Excavator Spare Parts Applied in Construction Machinery Field, We have now confident that we can easily offer the premium quality products and solutions at resonable price, good after-sales services into the buyers. And we’re going to produce a dazzling future.

Best quality China Forged Excavator Parts, Rubber Track Pad, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.