Factory directly Excavator Bucket Pin Removal Tool - Excavator Arm Pin Hitachi EX200 – JiaLe

Factory directly Excavator Bucket Pin Removal Tool - Excavator Arm Pin Hitachi EX200 – JiaLe Detail:

Product Details

|

Arm pin |

|||

|

Material |

45# |

Part No. |

EX200 |

|

Color |

Bule or Customer Required |

Logo |

JALE or Customer Required |

|

MOQ |

10pc |

Packing |

Plywood Pallet or Customer Required |

|

Delivery time |

15-20days(one container) |

Suitable machine |

All Brands |

|

Warranty |

36 months |

Loading port |

Qingdao; Lianyungang; Rizhao… |

|

Certificates |

ISO9001,SGS |

Payment |

T/T;L/C; Ail Trade Assurance; Western Union… |

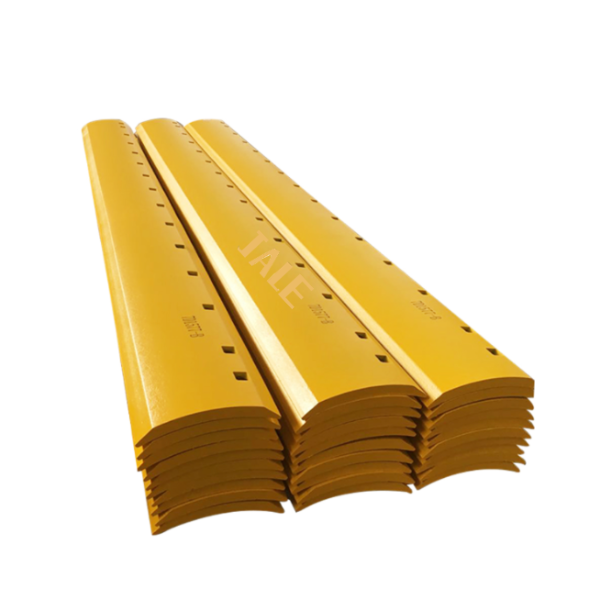

Details Display

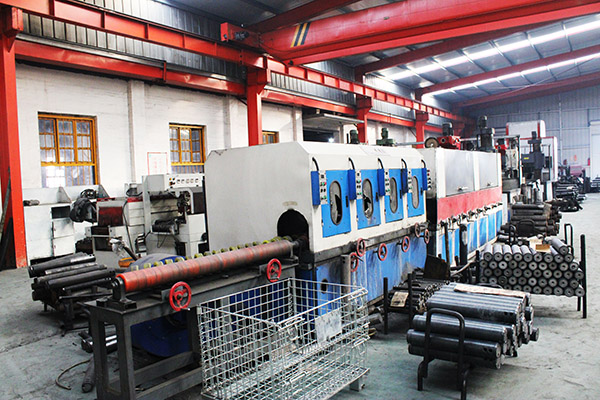

Production process

Round bound -> Cutting -> Quenching and tempering -> Rough machining -> Induction hardening -> Tempering Grinding -> Quenching hardness -> Completed

Advantage

Features

Crack Resistance and Abrasion Resistance

After quenching and tempering, the pin undergoes mid frequency induction hardening, which ensures sufficient core strength and wear resistance of the external surface.

After carburization, the pin bush undergoes internal and external mid frequency induction hardening, which ensures reasonable core hardness and wear resistance of internal and external surfaces.

Excellent lubrication performance

The most practical 8-shaped oil groove is adopted to ensure that the bushing has the best lubrication effect and prolong the service life of the bushing.

Longer Antirust

The original bucket bushing has been wiped with the good antirust oil and well packed, the black one has been finished with electrophoresis treatment, which ensures our bushing can be kept for a long time

Parameters

|

Bucket Pin |

|||

|

Diameter |

Length Range |

Diameter |

Length Range |

|

13 |

45-160 |

70 |

113-650 |

|

15 |

45-158 |

76 |

146-463 |

|

20 |

48-165 |

80 |

210-740 |

|

25 |

71-173 |

85 |

210-1050 |

|

28 |

45-125 |

88 |

140-710 |

|

30 |

75-193 |

90 |

133-800 |

|

32 |

88-241 |

95 |

210-990 |

|

35 |

103-260 |

100 |

120-960 |

|

38 |

123-227 |

105 |

315-1001 |

|

40 |

150-285 |

110 |

260-1040 |

|

45 |

185-298 |

115 |

290-1040 |

|

50 |

79-371 |

120 |

282-870 |

|

52 |

115-805 |

126 |

300-925 |

|

55 |

105-900 |

130 |

256-980 |

|

57 |

122-1020 |

134 |

278-980 |

|

60 |

170-1020 |

145 |

295-1080 |

|

65 |

119-699 |

150 |

338-1290 |

|

Be customized according to customer requirements |

|||

Structures

Why Choose JALE Bucket Pins?

Choosing a good bucket pins manufacturer mainly depends on two points: one is that the quality of the product must pass, because the quality of the product directly affects the use of customers, the bucket pin is a vulnerable product, so the wear life directly affects customer satisfaction Spend!

The second is the price. In terms of price, JALE bucket pin axle maintains an absolute advantage in the market, especially for dealers. Under the environment of the new normal of the market economy, demand is declining, and only a more advantageous manufacturer can hold profits. To survive, we use automated mechanized production to effectively control the process to improve production efficiency, thereby reducing production costs, so we now have an absolute price advantage compared with other products!

Product detail pictures:

Related Product Guide:

That has a sound business credit history, outstanding after-sales service and modern producing facilities, we have earned an superb popularity amid our buyers across the planet for Factory directly Excavator Bucket Pin Removal Tool - Excavator Arm Pin Hitachi EX200 – JiaLe , The product will supply to all over the world, such as: Cannes, Guyana, Argentina, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Let us join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to provide you with high quality and efficient services.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.