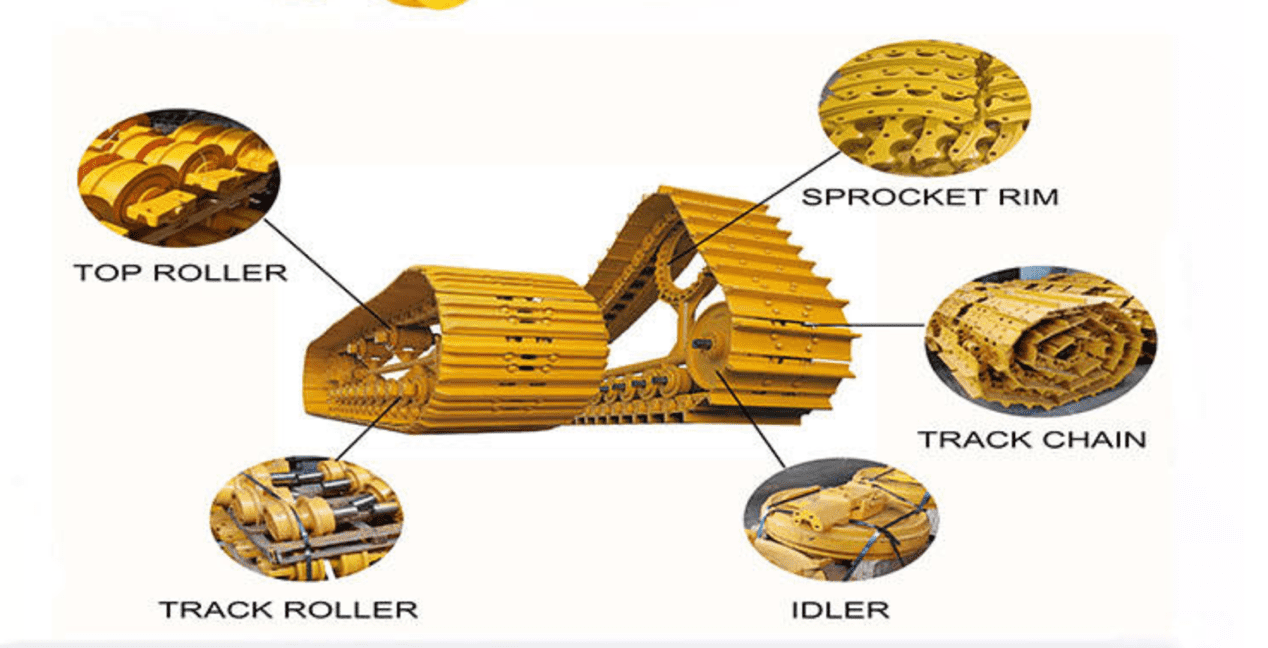

1. TRACK Roller

In the work should try to avoid the roller soaking in muddy water for a long time.

After the work is completed every day, the single-sided crawler should be propped up, and the walking motor should be driven to shake off the dirt, gravel and other debris on the crawler.

In winter construction, the roller must be kept dry, because there is a floating seal between the outer wheel of the roller and the shaft. If there is water, it will form ice at night. When the excavator is moved the next day, the seal and the ice will be damaged. Scratches cause oil leakage.

The damage of the rollers will cause many failures, such as walking deviation, walking weakness and so on.

The carrier wheel is located above the X frame, and its function is to maintain the linear motion of the chain rail. If the carrier wheel is damaged, the track chain rail will not be able to maintain a straight line.

The carrier roller is a one-time injection of lubricating oil. If there is oil leakage, it can only be replaced with a new one. During the work, try to avoid the roller being immersed in muddy water for a long time. Too much dirt and gravel build up hindering the rotation of the idler rollers.

3. FRONT IDLER

The guide wheel is located in the front of the X frame, which consists of the guide wheel and the tension spring installed inside the X frame.

In the process of operation and walking, keep the guide wheel in front, which can avoid abnormal wear of the chain rail, and the tensioning spring can also absorb the impact brought by the road surface during work and reduce wear and tear.

4.SPROCKET

The driving wheel is located at the rear of the X frame, because it is directly fixed on the X frame and has no shock absorption function. If the driving wheel travels in the front, it will not only cause abnormal wear on the driving ring gear and chain rail, but also adversely affect the X frame. The X frame may have problems such as early cracking.

The travel motor guard plate can protect the motor, and some dirt and gravel will be introduced into the inner space, which will wear the oil pipe of the travel motor, and the water in the soil will corrode the joints of the oil pipe, so the guard plate should be opened regularly. Clean up the dirt inside.

The crawler is mainly composed of crawler shoe and chain link, and the crawler shoe is divided into standard plate and extension plate. Standard plates are used for earthwork conditions, and extension plates are used for wet conditions.

The wear on the track shoes is the most serious in the mine. When walking, the gravel will sometimes get stuck in the gap between the two shoes. When it comes into contact with the ground, the two shoes will be squeezed, and the track shoes will easily bend. Deformation and long-term walking will also cause cracking problems at the bolts of the track shoes.

The chain link is in contact with the driving ring gear and is driven by the ring gear to rotate. Excessive tension of the track will cause early wear of the chain link, ring gear and idler pulley. Therefore, according to different construction road conditions, it is necessary to adjust the tension of the crawler.

Precautions:

Excavators are high-tech precision equipment combined with “electromechanical and hydraulic”. Maintenance not only requires experienced maintenance masters, but also needs to be supplemented by precision equipment calibration; in order to avoid repeated repairs of excavators, please choose experienced and well-equipped Regular repair shop.

Excavator maintenance often costs tens of thousands of dollars. In order to reduce the risk of wasting time and money for repeated maintenance by the owner, please choose an excavator repair manufacturer that you have signed with.

Post time: Apr-24-2022