The materials excavated by the excavator are mainly soil, coal, silt, soil and rock after pre-loosening. Judging from the development of construction machinery in recent years, the development of excavators is relatively fast, and excavators have become one of the most important construction machinery in engineering construction.

The first generation of excavators: the emergence of electric motors and internal combustion engines made excavators have advanced and suitable electric devices, so various excavator products were born one after another. In 1899, the first electric excavator appeared. After the First World War, diesel engines were also used in excavators. This diesel engine (or electric motor) driven mechanical excavator was the first generation of excavators.

The second generation of excavators: With the extensive use of hydraulic technology, the excavator has a more scientific and applicable transmission device. Hydraulic transmission instead of mechanical transmission is a great leap in excavator technology. The first hydraulic excavator in Germany was born in 1950. Mechanical transmission hydraulic is the second generation of excavators.

The third generation of excavators: The wide application of electronic technology, especially computer technology, enables the excavator to have an automated control system, and also makes the excavator develop in the direction of high performance, automation and intelligence. The germination of mechatronics occurred around 1965, and the adoption of mechatronics technology on mass-produced hydraulic excavators was around 1985, when the main purpose was to save energy. Excavator electronics are the hallmark of the third generation of excavators.

Excavator parts are mainly composed of two parts: mechanical parts and electronic parts.

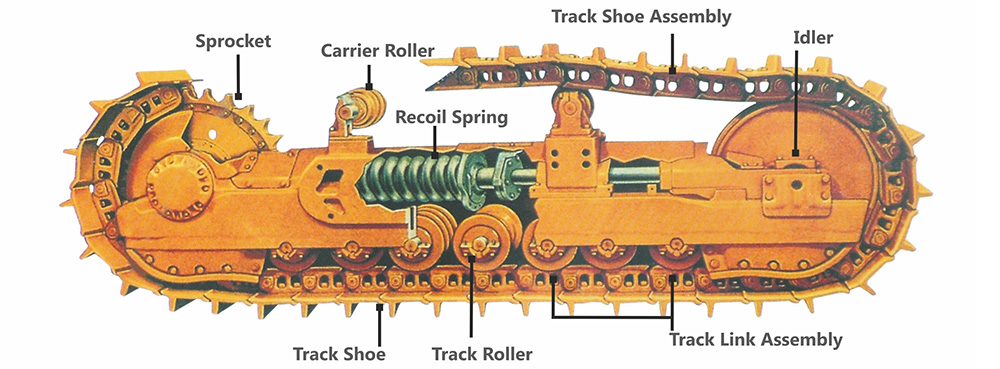

1. Mechanical parts are purely mechanical parts to provide power support, mainly including hydraulic pumps, grab buckets, booms, tracks, engines, etc.

2. Electronic accessories are the driving control part of the excavator, which are used to drive the mechanical parts to perform reasonable work, mainly including computer version, hydraulic flow controller, angle sensor, diesel meter, fuse, ignition switch, oil suction pump, etc.

The mechanical parts and the drive control part are complementary to each other. The electronic control part is used to drive and coordinate the effective work of each mechanical part. The situation of the mechanical part is fed back to the electronic control part through the electronic parts, so as to coordinate the work of the excavator more effectively to reach its highest working efficiency.

The working device is the main part of the hydraulic excavator. It is mainly used to excavate the soil below the stop surface, but it can also excavate the soil below the maximum cutting height. In addition to digging, ditching and loading, it can also perform simple site leveling work. The excavation operation is suitable for excavating the soil of grade Ⅰ~Ⅳ, and the hydraulic hammer or blasting method is required for the above grade Ⅴ.

The backhoe working device is composed of boom, stick, bucket, rocker, connecting rod, and hydraulic pipelines of the working device including boom cylinder, stick cylinder and bucket cylinder.

Post time: Jan-11-2022